Introduction of spring-loaded safety valve structure [picture]

We know that safety valves can be divided into vertical type, lever type, pilot type and spring type safety valve according to the structure. Today we mainly introduce the spring type safety valve and its structure.

So what is a spring-loaded safety valve? What is its organization like?

A spring-loaded safety valve means that the valve flap or plunger and other seals are locked by the elastic pressure of the spring. Once the pressure of the pressure vessel is abnormal, the high pressure generated will overcome the spring pressure of the safety valve, so the locking device is opened to form A pressure relief channel is used to release the high pressure.

The spring-loaded safety valve is divided into two types: full lift type and micro lift type according to the different opening height of the valve disc. The full lift type has a large discharge volume and good resilience, which is suitable for liquid and gas media. The micro lift type is only suitable for liquid media.

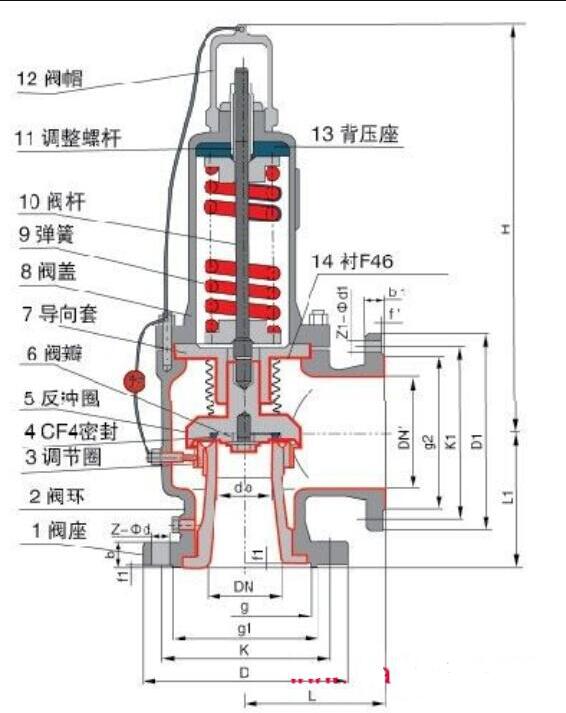

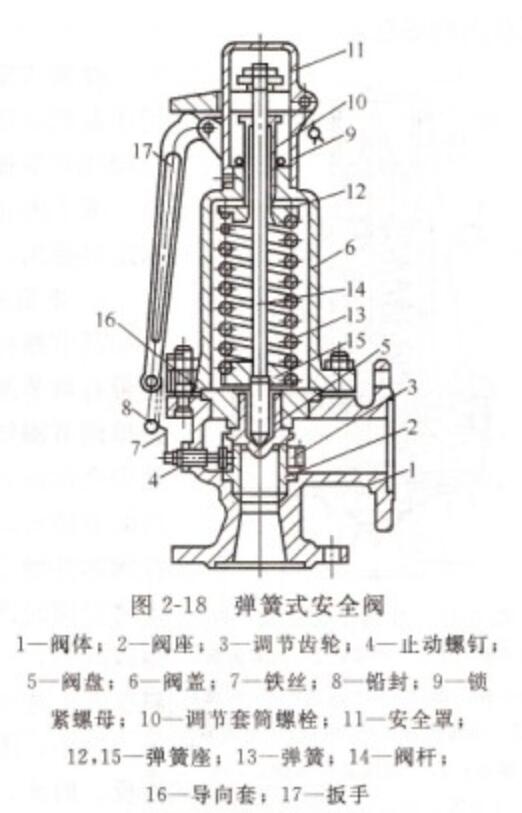

The spring type safety valve is mainly composed of a valve body, a valve seat, a valve disc, a valve core, a valve stem, a spring and an adjusting screw, etc. The structure diagram is as follows:

图1

figure 2

Description of some structural parts of spring-loaded safety valve:

1. Nozzle type valve seat: The valve seat is a Vivare nozzle type valve seat. When steam flows through the outlet of the valve seat, it reaches the speed of sound. The emission coefficient is large. Eclipse, long life.

2. Thermoelastic valve disc: The valve disc is designed as a thermoelastic structure, which uses its slight deformation under the medium pressure to improve the sealing ability and overcome the front leakage phenomenon of the safety valve when the pressure is close to the set pressure under the medium pressure. The sealing surface of the valve disc adopts advanced laser quenching technology to improve the hardness, wear resistance and impact resistance.

3. Adjusting nut: By adjusting the adjusting nut to adjust the spring compression, the valve can easily and quickly obtain the accurate setting pressure.

4. Back pressure adjustment sleeve: an auxiliary mechanism for adjusting the back pressure of the valve disc. Through the adjustment of the back pressure adjustment sleeve, an appropriate return pressure difference can be obtained. When increasing, the valve back pressure is reduced. When lowering, the valve back pressure is increased.

Service Hotline:0577-85981234

Service Hotline:0577-85981234

Position:

Position: